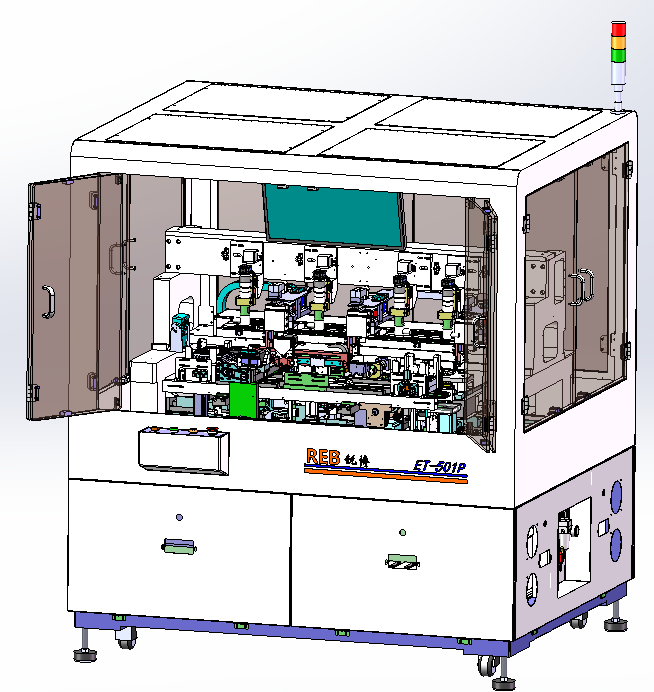

High-Precision Eutectic Die Bonder

The ET-501P is a dedicated production machine designed to eutectically bond the submount and chip (LD) onto a TO56 header through a controlled heating process.

Overall Machine Layout:

Dimensions: X 1640 Y 1320 Z 1820

Machine Composition:

Machine Description:

The ET-501P is a specialized production system designed to bond submounts and laser diode (LD) chips onto TO56 headers through a controlled heating eutectic process.

This system enables eutectic bonding of both the submount and chip onto the same header simultaneously, simplifying the packaging process and improving yield.

Submounts and chips are loaded from blue tapes, independently identified, picked, placed, and aligned. Headers are supplied and unloaded via an inline conveyor system, enhancing production efficiency.

The chip emission line is recognized and aligned by vision, with position and angular compensation to ensure placement accuracy.

Pick-and-place nozzles use vacuum suction with flow sensors to verify successful pickup, supported by a nitrogen blow-off for vacuum release. This ensures production reliability. Pickup force is minimal and stable.

The eutectic stage features a constant-temperature mechanism with stable thermal settings and nitrogen protection during bonding, ensuring high reliability of eutectic joints.

The X and Y axes of the robotic arm are driven by linear motors, providing high accuracy while improving throughput.

Operating Principle & Functions:

The ET-501 is used in the COB process to bond submounts and LD chips onto headers via eutectic heating.

Manual Loading:

1.Operators place submounts and chips into the respective wafer handling units.

2.Operators load headers into the header feeder unit.

Automated Workflow:

1.After startup, the inline conveyor transfers headers to the worktable and secures them.

2.The header handling robot picks up the header and transfers it to the flipping finger unit.

3.The flipping finger places the header into the eutectic stage.

4.CCD1 locates the submount.

5.The submount pick-and-place robot picks up the submount and transfers it above CCD7.

6.CCD7 performs backside recognition and correction of the submount.

7.The submount robot places the submount at the designated position on the header.

8.CCD5 locates the chip.

9.The chip pick-and-place robot picks up the chip and transfers it to the alignment stage.

10.CCD4 performs front-side recognition and correction of the chip.

11.The chip placement robot transfers the chip above CCD6.

12.CCD6 performs backside recognition and verifies compensation accuracy.

13.If placement is incorrect, another front-side correction is performed.

14.The chip placement robot places the chip onto the submount for eutectic bonding (with CCD2 and CCD3 monitoring the process in real time).

15.The flipping finger removes the bonded product from the eutectic stage and rotates it 90°.

16.The header handling robot transfers the bonded product into the header fixture on the worktable.

17.Once all headers in the fixture are completed, the inline conveyor transfers the bonded products to the unloading unit.